A Lamoureux & Sons knife requires minimal maintenance to prolong its life and efficiency. The blade is made of high-grade stainless steel, CPM-S30V, which is highly resistant and maintains its sharpness.

Regular maintenance

Blade maintenance

After each use, wash the blade with a soft, damp cloth and wipe dry immediately. Slight oxidation may be noticed, and even slight traces of rust in the event of poor maintenance. In such cases, you can use polishing products available from hardware stores.

Handle maintenance

We work mainly with stable exotic woods such as Ebony, Cocobolo, Micarta and Deer Horn. You can wash the handle with lemon oil soap, use a soft, dry cloth to dry it well, then apply Lamoureux & Sons handle wax to preserve its luster and protect it from moisture.

Caring for your leather case

We suggest applying Lamoureux & Sons leather case wax to keep the leather supple and waterproof, then wipe off any excess with a soft cloth.

How to sharpen your knife

Prepare your equipment

We recommend using Japanese sharpening stones in combination with light vegetable sharpening oil. The oil dissipates material deposits, keeping the stone clean, reducing heat and facilitating movement.

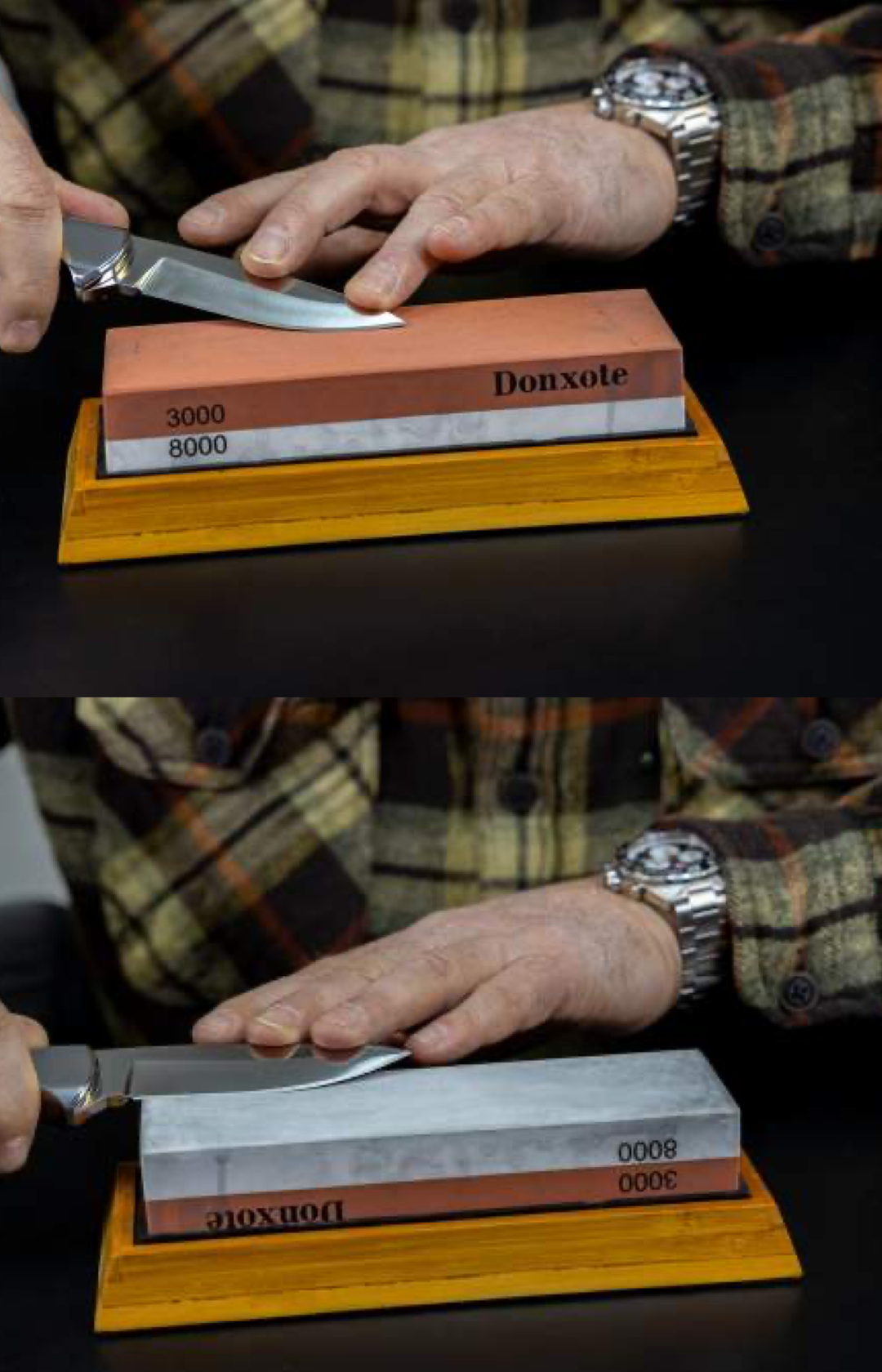

The Donxote stone set with grades of 400, 1000, 3000 and 8000 grit per inch is particularly effective.

The right position

Always hold your knife by the handle with the cutting edge away from you. Always place the blade on the stone with the cutting edge at an angle of between 20 and 25 degrees (as illustrated).

If your blade stops cutting

Start with a rough-grained natural stone (between 400 and 600) and finish with a fine-grained natural stone (between 800 and 1,000).

Make forward thrusting movements. At the end of this movement, raise the blade so that it does not touch the stone, and return the blade to its starting position.

For the other side of the blade; push towards you using the same method of movement, always applying medium force to the blade. Too much force will damage the stone and leave a solid deposit of material on the edge of the blade. Approximately a dozen passes will be required for each part of the blade, i.e. the cutting edge, primer and tip.

Then turn your stone 90 degrees and repeat the operation in the same direction. Always keep your stone moist with oil, avoiding excessive oil build-up.

Always push evenly and steadily along the entire length of the stone, making sure to keep the entire surface of your blade in contact with the stone.

Move up to the next grade of stone and repeat the same operation to sharpen more and more.

For blades requiring fine or touch-up sharpening

Start right away with a fine-grained natural stone (between 1000 and 3000).

Gently push the blade forward. At the end of this movement, raise the blade so that it does not touch the stone, and return it to the starting position.

For the other side of the blade; push towards you using the same method of movement, always applying medium force to the blade. Too much force will damage the stone and leave a solid deposit of material on the edge of the blade. Approximately ten passes will be required for each part of the blade, i.e. the cutting edge, tip and root.

Then turn your stone 90 degrees and repeat the operation in the same direction. Always keep your stone moist with oil, avoiding excessive oil build-up.

Always push evenly and steadily along the entire length of the stone, making sure to keep the entire surface of your blade in contact with the stone.

Move up to the next grade of stone and repeat the same operation to sharpen more and more.

Occasional cleaning

If your blade has lost its luster, is stained or simply needs a thorough cleaning, you can clean it with stainless steel cleaner and luster and a soft cotton cloth. This will loosen and remove the tiny deposits accumulated on your blade.

Spray the cleaner onto your cloth, never directly onto the blade. Then wipe the blade with the cloth using a gentle, even motion along the entire length of the blade.